Multi N / C pharma UV – TOC analysis at very low levels

An effective TOC instrument based on wet chemical UV digestion for TOC analysis in ultra-pure water samples and for validation of cleaning processes with an injection volume up to 20.0 ml.

Characteristics

- TOC determination in direct NPOC mode, without blank value, for best sensitivity and precision

- TOC measurement <1 ppm without oxidation reagent

- Lowest operating cost – no catalyst or combustion tube, no additional reagents required

- Extended working range up to 10,000 ppm with the help of oxidation reagents that can be easily manufactured by the user

Multi N / C pharma HT -flexible analysis of TOC / TN

A versatile instrument with high temperature incinerator for analysis of TOC / TN in ultra-pure water and for validation of cleaning processes. As an option, there is also direct combustion of swabs which makes it possible to determine insoluble or almost insoluble contaminants in the cleaning validation for TOC.

Characteristics

- TOC determination in direct NPOC mode for best precision in the ultra-low content range

- Injection volume up to 3.0 ml

- Optional cleaning validation for TN

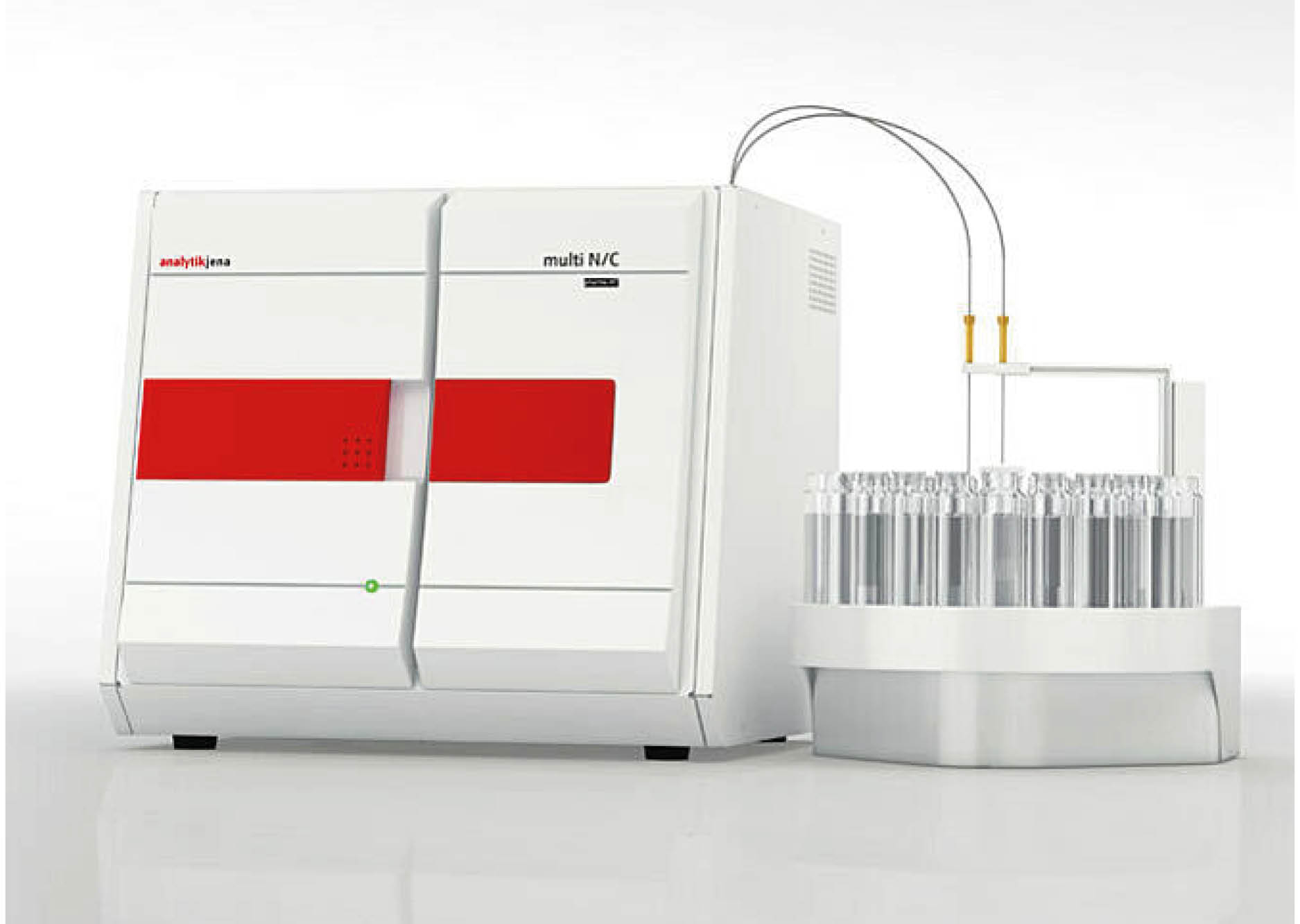

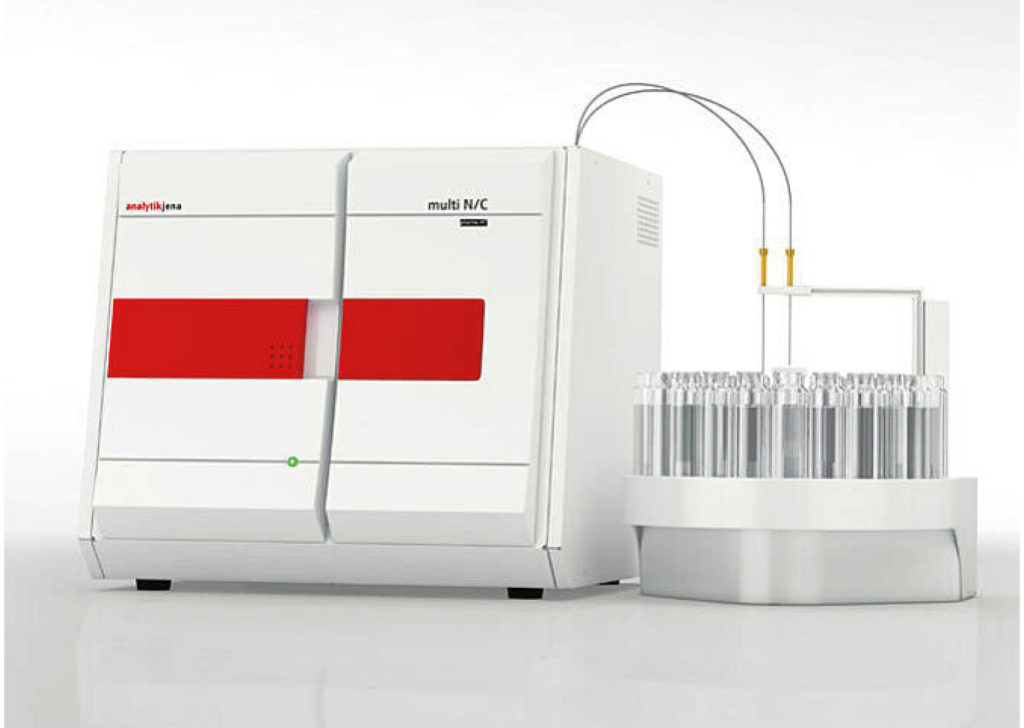

Multi N / C 3100 pharma – large sample flows for TOC / TN analysis

The instrument is based on catalytic combustion at high temperature and offers a large dynamic working range with efficient cleaning function, high degree of automation and parallel sample fold for large sample flow.

Characteristics

- TOC determination in direct NPOC mode for best precision in ultra-low content range

- Injection volume up to 1.0 ml

- Covers a concentration range for TOC between 0 – 30,000 ppm

- Automatic sample acidification and effective reverse rinsing function to prevent contamination / carry-over if concentrations change

Multi N / C 2100S pharma – the specialist for analysis of total protein

Instruments for analysis of TN with catalytic combustion at high temperature and CLD determination for efficient protein analysis in vaccine production or cleaning validation for TN. Minimal testing is required and it is possible to automate to a great extent.

Characteristics

- No sample contamination / carry-over thanks to direct injection without septa via a microliter routine syringe and efficient cleaning

- Low sample volumes, typical injection volume of 50 – 200 μl (max.1.8 ml). Save costs for expensive matrices, e.g. in the field of vaccine quality control

- Large working range from 0 – 200 ppm TN High degree of automation for large test series (up to 112 test positions for HPLC vials) 24-hour operation without monitoring possible thanks to a built-in self-control system (SCS)

Do you have any questions? Do not hesitate to contact us.